GALLANTT ADVANCE

FE 550D TMT BARS

TRANSFORMING THE FACE OF INDIAN INFRASTRUCTURE

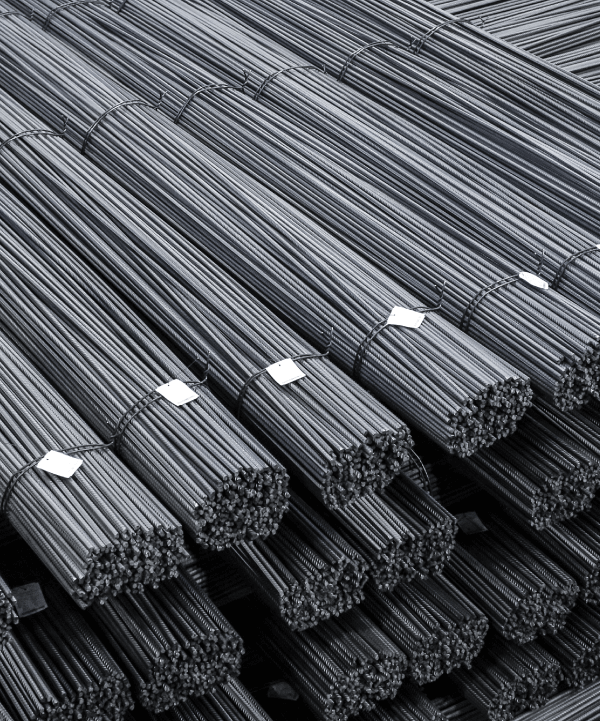

TMT Bars form the backbone of every construction, be it foundation, column, beam, or the slab in any RCC structure across both commercial and residential projects. TMT bars have used all projects as a prime element providing the required shape, strength, ductility, and durability to every civil structure.

The quality of the TMT bar used in every civil structure is critical to the overall quality of the structure. As the country is committed to building world-class infrastructure, only superior quality TMT bars must be used. Gallantt Group, with its modern & sophisticated Integrated steel plants, is delivering such superior quality Fe550 & Fe550D TMT bars which goes a long way to impart strength and durability to our country’s growing demand for quality construction raw materials.

WE BELIEVE IN STEEL

Gallantt Group is one of the leading Indian conglomerates which is vertically integrated with end to end steel manufacturing processes through their multiple states of art fully-integrated steel plants coupled with captive power generation located at Kutch in Gujarat & Gorakhpur in Eastern U.P. A leading producer of steel long products, i.e. TMT bars with DRI Plants, steel melt shop, rolling mills, and captive power plants. The group has an extensive and excellent sales network countrywide to serve its customers with their flagship product under the brand “GALLANTT ADVANCE 550 D” TMT bars.

We are one of the fastest and most aggressively growing organizations which has captured a substantial market of TMT bars in the state of Uttar Pradesh and Gujarat within a short period.

The management teams of the group are astute industry professionals and successful entrepreneurs with extensive working experience in the iron & steel industry. Each of the members brings valuable business insight to the overall operational and management process. The advisory board is pioneered with industry veterans having skills and expertise to work alongside the management to achieve all its goals. The Group employs to approx. 4000+ personnel directly and indirectly.

QUALITY THAT STANDS TALL

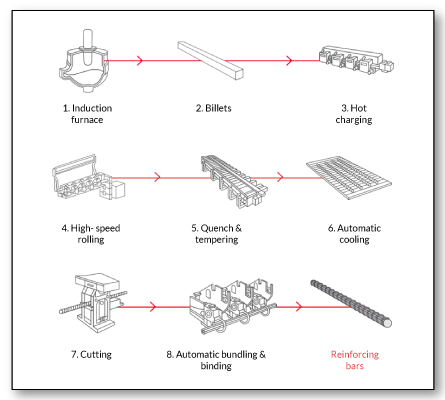

CLEANEST AND PUREST STEEL MAKING

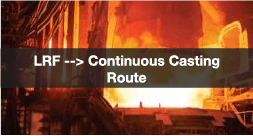

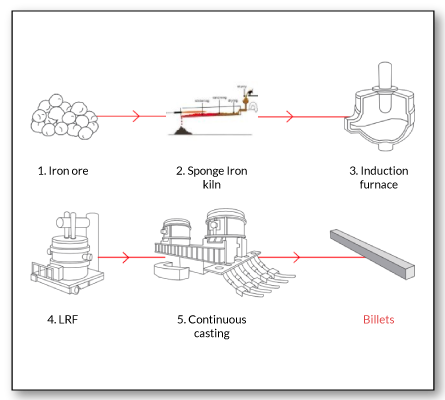

In the induction route, phosphorus and sulphur is controlled through de-phos- phorisation and de-sulphurization in a ladle refining furnace (LRF). Refining occurs in the primary and secondary stages in LRF where both the harmful elements are reduced. In our steel-making process, the use of LRF ensures the removal of solid and gaseous inclusions from steel to produce clean & pure steel. LRF is a very important tool in steel-melting shops and usage of the same helps increase the quality of our finished products.

This improvised, integrated route produces steel which is as good as steel produced through any other route in terms of delivering superior chemical composition and physical properties for our TMT bars. Our induction furnace coupled with LRF for final refining is absolutely capable of producing steel that meets quality standards required for infrastructure and construction according to international and BIS standards.

GALLANTT ADVANCE Fe550D

Best in its class

Gallantt Advance TMT bar distinguishes itself from local generic producers and places it next to primary products available in the market

Virgin iron ore as raw material

Gallantt Advance TMT uses virgin iron for manufacturing of billets inhouse which are then rolled into TMT bars

Superior yield strength

Delivers Best UTS/YS Ratio with Max Elongation

High ductility for max flexibility

Bends & re-bends at smaller diameters without cracking due to inherent microstructure

Earthquake resistance

Perfect combination of UTS/YS ratio & uniform elongation can absorb cyclical loading during earthquakes

Best in class accreditation

Surpassed minimum specified levels of BIS & other international- al standards

Fair pricing

Has predefined and transparent pricing

Upto 10 % Savings on steel cost

Gallantt Advance TMT bars have higher yield strength and can take greater loads, thus reducing steel consumption at the site when compared to local brands thus saving on steel

LOOKING FOR EXTRA : THE Fe 550D EDGE

MECHANICAL PROPERTIES

CHEMICAL PROPERTIES

MORE VALUE, MORE CONVENIENCE, MORE REACH

EXCELLENT AFTER SALES SERVICE COST

One of the largest & widespread sales network in UP, dedicated team of sales engineers to offer personalized services and advice to customers

5 – 7% SAVINGS ON STEEL

Gallantt Advance TMT bars have higher yield strength and can take greater loads, thus reducing steel consumption at site when compared to local brands thus saving on steel

DURABLE CONSTRUCTION

Manufactured for undertaking Max elongation during earthquakes, Gallantt Advance TMT bars gives your construction 5x more strength when compared to locally made TMT Bars

2000+ dealer network | Free delivery* within municipal limits | Hassle-free delivery experience

PRODUCT SPECIFICATIONS

CHEMICAL PROPERTIES

MECHANICAL PROPERTIES

WEIGHT ADVANTAGES

OUR ESTEEMED CLIENTS

INDUSTRY APPLICATION

TRANSFORMING THE FACE OF INDIAN INFRASTRUCTURE

TMT Bars form the backbone of every construction, be it foundation, column, beam or the slab in any RCC structure across both in commercial and resedential projects. TMT bars are used all projects as a prime element providing the required shape, strength, ductility and durability to every civil structure.

Quality of the TMT bar used in every civil structure is critical to the overall quality of the structure. As the country is committed towards building world class infrastructure, it is absolutely mandatory that only superior quality TMT bars are used. Gallantt Group, with its modern & sophisticated Integrated steel plants, is delivering such superior quality Fe500 & Fe550D TMT bars which goes a long way to impart strength and durability to our country’s growing demand of quality construction raw materials.

REAL ESTATE

INFRA

METRO